Industrial Monitor: Enhancing Visibility, Control, and Efficiency in Industry

Industrial monitors are specialized display systems designed to operate reliably in demanding industrial environments such as manufacturing plants, control rooms, oil and gas facilities, transportation hubs, and energy utilities. Unlike consumer-grade monitors, industrial monitors are engineered for durability, long operational life, and consistent performance under harsh conditions. They play a critical role in visualizing data, monitoring processes, and supporting real-time decision-making across a wide range of industrial applications.

One of the defining characteristics of industrial monitors is their robust construction. These monitors are built to withstand extreme temperatures, humidity, dust, vibration, and electrical interference. Many models feature rugged metal enclosures, reinforced glass, and high ingress protection (IP) ratings, making them suitable for use in environments where standard displays would fail. This durability ensures minimal downtime and lower maintenance costs, which are crucial in continuous industrial operations.

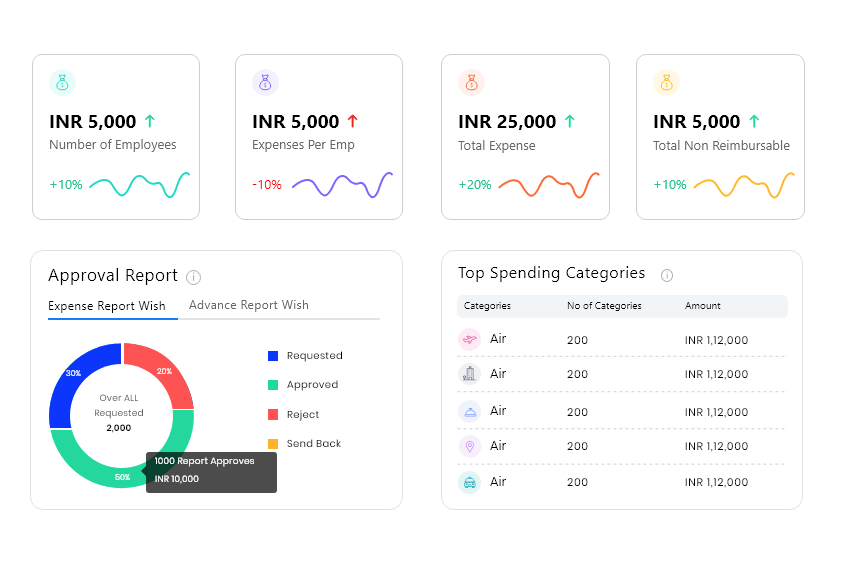

Industrial monitors are widely used in automation and control systems. In manufacturing facilities, they are integrated with programmable logic controllers (PLCs), supervisory control and data acquisition (SCADA) systems, and human-machine interfaces (HMIs). By displaying real-time production data, machine status, alarms, and performance metrics, industrial monitors help operators maintain process stability, quickly identify issues, and improve overall productivity. Clear and reliable visualization is essential for reducing errors and enhancing operational safety.

Another important aspect of industrial monitors is display performance. They are designed to offer high brightness, wide viewing angles, and excellent contrast to ensure readability in various lighting conditions, including direct sunlight or low-light control rooms. Touchscreen functionality is also commonly integrated, enabling intuitive interaction through gloves or in wet and dusty environments. Technologies such as resistive, capacitive, and infrared touch are selected based on specific industrial requirements.

Industrial monitors also support a wide range of connectivity options. Multiple input interfaces such as HDMI, DisplayPort, VGA, and DVI allow seamless integration with legacy systems as well as modern industrial PCs and embedded devices. This flexibility helps industries upgrade their visualization infrastructure without completely replacing existing systems, thereby optimizing capital investment.

From an efficiency and safety perspective, industrial monitors contribute significantly to operational excellence. By providing centralized and accurate visual information, they enable faster response times, improved coordination, and better compliance with safety standards. In sectors such as power generation, transportation, and chemical processing, reliable visual monitoring is essential for preventing accidents and ensuring regulatory compliance.

Industrial monitors are a vital component of modern industrial ecosystems. Their rugged design, superior display quality, flexible integration, and long lifecycle make them indispensable for process monitoring, automation, and control. As industries continue to embrace digital transformation, smart factories, and Industry 4.0 initiatives, the demand for advanced industrial monitors is expected to grow, reinforcing their importance in achieving efficiency, reliability, and sustainable industrial operations.